- Combines high temperature capability with an advanced controller at a very affordable price

- Heat to 1600°C in less than one hour

- Program allows you to ramp temperature at controlled rates

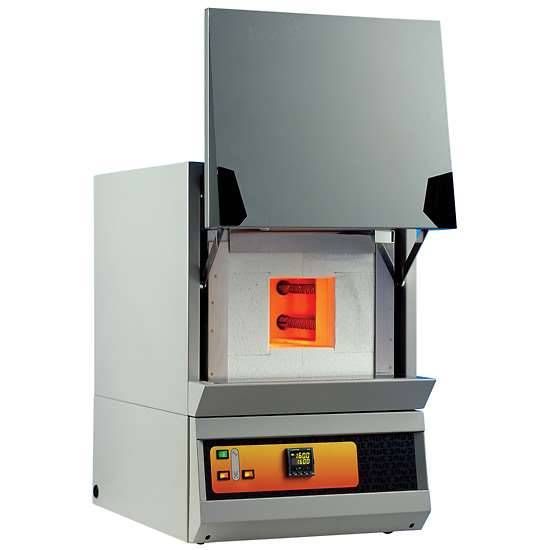

This furnace’s high-temperature output is great for heat treating, reacting studies, sintering processes, and ceramic firing. Powerful silicon carbide heating elements ensure quick heating and a uniform chamber temperature. Quality chamber construction includes a durable refractory brick entrance, a long-life cast alumina hearth, and energy-efficient ceramic fiber insulation.

Engineered with your safety in mind, the furnace has a double shell construction to keep the outer case cool, a door switch that disengages power when the door is opened, and the easy-to-operate vertical-swing door keeps heat away when opened. Furnace is equipped with a chimney vent for process exhaust.

Furnace temperature controller utilizes PID technology for highly accurate 16-segment programmability with up to 8 ramps (either up or down) and 8 dwells (time soaked). A three-color LCD display simultaneously indicates actual furnace temperature and set point temperature. Temperature may be displayed in °C or °F. Unique control system increases power to the heating elements to compensate for element resistance change during the aging process.