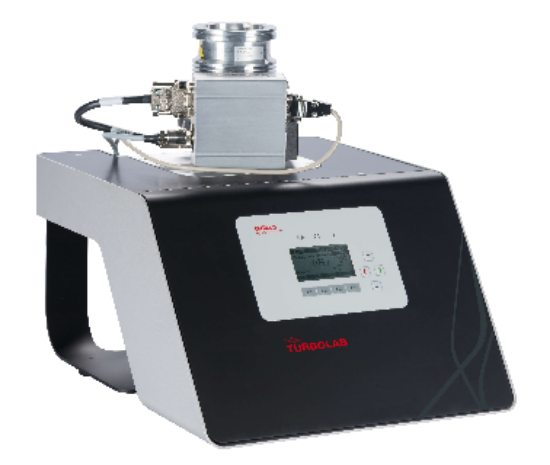

The all new smart high vacuum TURBOLAB Turbo Pumping Systems from Leybold Germany are compact, fully assembled, completely oil free and ready to use. The TURBOLAB range covers a range of turbo pumps from 80 l/s to 450 l/s with the best price to pumping ratio available on the market.

A choice of backing pumps (1m3/hr to 30m3/hr) and mounting options (tabletop or cart) are available to suit the most demanding high vacuum applications.

The TUBOLAB 80 High Vacuum Pumping Station includes the following:

- Leybold Germany SL80 Turbo Pump with 65 l/s N2 pumping speed - Bearing MTBF of 200,000+ Hours

- Leybold Germany DIVAC 0.8T Oil Free Diaphragm Pump with Boost mode

- Tabletop frame design

- Smart TPU Display with integrated webserver for PC/Smart Device control

- Integrated data-logging

- Integrated condition monitoring for unrivalled safety/interlock control

- Remote control with configurable analogue/digital I/O

- Monitor 2x vacuum gauges (optional)

- Up to 6x accessories can be easily integrated

Highlights of the TURBOLAB Range:

- Enhanced pump performance

- Compact mobile design

- Small foot print

- Easy to relocate pumps out and away from the frame

- Backlight display (control/monitoring/configuration)

- Monitored data like frequency, temperature, current or pressure ard automatically stored to a data log file in the TURBOLAB. Users can easily view the log file with the TURBOLAB data viewer software tool which can be downloaded for free from our website. Alternatively, the last 512 data points can be viewed from the TURBOLAB data viewer in the web server

- Covering more applications with a full range of high vacuum and dry or wet forevacuum pumps to cover more high vacuum applications

- Benchmark turbostation offering dedicated ports for the connection of

- Six different accessories

- Two gauges

- Benchmark functionality, reliability and design

- Prepared for worldwide voltage coverage

- Best Price-to-performance ratio on the market

Below is a full list of plug and play accessories:

- Purge gas or venting valve

- Air or Water Cooling

- Flange Heater

- Foreline Vent Valve

- SECUVAC Safety Valve (prevent back venting)

- Absorption Trap

- Exhaust Filter

- 2x Vacuum Gauges

- Wide Range High Vacuum (ATM to 10-9 mbar)

- Roughing Line Gauge (ATM to 10-4 mbar)

- ISO K or CF Flange connections available

- Relocation Kits available to relocate the pumps away from the frame to minimise vibration on the application.

Monitoring & Data Analysis

We understand data is critical for research and data management can be tricky, that is why we simplified this for you.

All critical parameters and conditions (like errors, warnings, frequency, temperature, etc.) are logged to an internal memory automatically based on a default time interval which you the user can change very easily.

The built-in Webserver allows you to analysis the conditions and events of your TURBOLAB system.

Opening the trend view on your laptop or mobile device will display the events overtop of your trended parameter. This allows you to quickly compare the data surrounding your system events. This new way of looking at the data around the event helps to diagnosis conditions that effect your system.

Typical Applications

- Analytical instrumentation

- Spectroscopy

- Tube manufacturing

- Beam guidance systems

- Micro balances

- Sputtering and evaporating systems

- Surface physics

- Laboratories

- Photonics

- Cryogenics/Cryostats