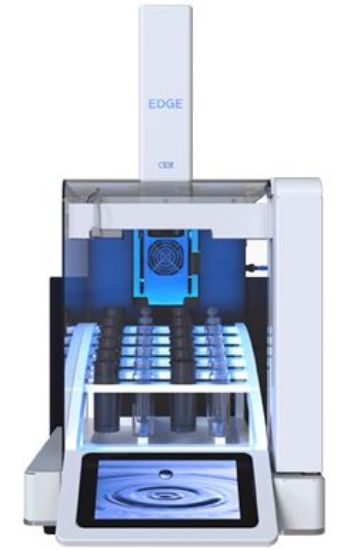

EDGE™

The new leading edge of sample preparation.

Overview

The Q-Cup technology combines the process of Pressurized Fluid Extraction and Dispersive Solid Phase Extraction in one instrument. You’ll have all the benefits of both techniques yielding faster results. Regardless of sample size, matrix, or use of sorbents, you can extract in only five minutes. This includes the filtering, cooling, and washing process.

Features

- Fastest technique available (5 minute cycle time)

- 12 samples in an hour (includes washing, filtering, & cooling)

- Q-Cups (sample holders) are easily assembled and cleaned

- Small footprint (about the size of an analytical balance)

- One technology with unlimited applications (Q-Cup Technology)

Energized Dispersive Extraction

With Q-Cup technology, Energized Dispersive Extraction is simple and fast for all applications. Extract semi-volatile organic compounds from soil, fat from food, phthalates from plastics, and many more applications with EDGE.

EDGE vs Traditional Solvent Extraction

EDGE is faster than any other traditional solvent extraction techniques. With its speed, compact size, and ease of use, there’s nothing like it available.

Energized Dispersive SPE

With Q-Cup technology, Automated Dispersive Solid-Phase Extraction (dSPE) is possible. EDGE is an alternative to QuEChERS for the extraction of pesticides. This new technology offers a more effective extraction and cleanup for difficult matrices.

Q-Cup Technology

A simple solution to a complicated problem.

The Q-Cup™ sample holder consists of just three easy-to-assemble pieces. The unique open cell concept creates a dispersive effect which promotes rapid extraction and filtration. No additional steps are required prior to analysis.

The Q-Cup is ultra-thin aluminum for efficient heating. It’s light-weight and easy to carry.

Worldwide Patents Pending

Load your samples in seconds.

Just add a Q-Disc, screw on the bottom, and add your sample; it’s that simple.

Easy Cleaning

The simple design lends itself to easy cleaning. A quick rinse is all you need.

Disposable Q-Discs

The Q-Discs are disposable, eliminating the need to clean.

The EDGE Process

Sample is Loaded

The Q-Cup is automatically loaded into the chamber by the auto sampler. The pressure cap then creates a pressurized seal on the top of the Q-Cup.

Sample is Loaded

Solvent is first added through the bottom to fill the gap between the chamber and Q-Cup, this aids in heat transfer. Then, solvent is added through the top of the Q-Cup to wet the sample.

As the chamber walls are heated, the pressure in the gap increases. This overcomes the pressure inside the Q-Cup, forcing the solvent to disperse into the sample.

Extract is Collected

Once the sample reaches temperature, the solvent is dispensded through the Q-Disc, the cooling coil, and into a collection vial.

Fast

20 times faster than most current techniques.

EDGE is fast, uses less solvent, and is cost effective making it the smart choice for every lab.

Technique |

Time (minutes) |

Solvent Usage (mL) |

Cost Effective |

| EDGE | 5 | 20 | $ |

| Microwave | 15 | 30 | $$ |

| QuEChERs | 30 | 23 | $ |

| Pressurized Fluid Extraction | 30 | 21 | $$$ |

| Soxhlet | 360 | 150 | $$ |

| Automated Soxhlet | 120 | 90 | $$$ |

| Ultrasonic | 60 | 300 | $$ |

Simple

Your pre-installed methods are just one touch away.

Right on the home screen, you have access to the One Touch™ methods. These are the pre-installed methods that make programming the EDGE quick and simple.

Flexible

Get better results with one technique.

- Dispersive Solid Phase

- Supported Liquid

- Pressurized Fluid

- Liquid Liquid

No need for multiple techniques for different samples, EDGE is the answer for all extractions, made possible by Q-Cup Technology. No matter your technique, you’ll extract a clear solution ready for analysis.

Compact

Its small size is a big advantage.

- The EDGE is only 14.25" wide

You can extract 48 samples an hour with 4 EDGE systems side-by-side on one bench top.

Extraction of Semi-Volatile Organic Compounds from Soil in Accordance with EPA 3545

Abstract

Semi-Volatile Organic Compounds (SVOCs) are a subgroup of Volatile Organic Compounds (VOCs) that have a high molecular weight and high boiling points. They are primarily composed of pesticides and herbacides. Prolonged exposure to these compounds, especially indoors, raises a public health concern. For example, many of these compounds have been listed by the US EPA as hazardous air pollutants (HAPs). This classification applies to pollutants that can cause serious health effects such as: allergies, asthma, endocrine and thyroid disruption, reproductive toxicity, fetal and child development delays, and even cancer. Soil is one of the most common matrices in which these compounds are present and the extraction of these compounds from soil can be a lengthy and tedious process. The CEM EDGE™ is a revolutionarily simple system for the rapid extraction of semi-volatile organic compounds (SVOCs) from soil that is more than six times faster than other automated techniques. With its patent pending Q-Cup Technology™ the EDGE™ makes the extraction process fast and simple and meets the requirements of EPA 3545.

Introduction

Semi-volatile organic compounds consist of substances with abroad set of chemical properties and structural features. These differences make it challenging to efficiently extract all analytes of interest with one method. Furthermore, the soil matrix from which the SVOCs are to be extracted is often complex with multiple components adding to the complexity of extraction. The CEM EDGE with Q-Cup Technology™ can effectively extract a difficult set of analytes from complex matrices with one simple method. Traditional methods, such as soxhlet, are very time consuming and use a large amount of solvent. Automated methods often require tedious sample preparation with complex sample holders. EDGE is the fastest exaction system available and uses a minimal amount of solvent. The Q-Cup sample holder is comprised of two easy-to-assemble pieces allowing the sample to be prepared in seconds.

Due to their persistent nature, SVOCs continue to accumulate and concentrate in our environment. To ensure our safety, these compounds need to be extracted, identified, and quantified. The accuracy of SVOC analysis is dependent on an efficient extraction. EDGE yields an efficient extract that is filtered, cooled, and ready for analysis in under 5 minutes. EPA 3545 is a method for the extraction of water-insoluble or slightly water-soluble volatile and semi-volatile compounds in soils, clays, sediments, sludges, and waste solids. EDGE meets the requirements of EPA 3545 and is preprogrammed with the methodology.

Total Fat Extraction of Hot Dogs and Potted Meat

Abstract

The extraction of fat from food is crucial in the food industry for product formulation and because food labels must report both saturated and unsaturated fat content. Furthermore, educated consumers want to know what is in their food and pay particular attention to the fat content. In an industry with lots of quality control and that is increasingly becoming more consumer driven, time becomes a critical factor. Food manufacturers are burdened with additional testing before product release, making speed of analysis a critical factor. In this application note, EDGE™ with its patent pending. Q-Cup Technology can extract total fat from hot dogs and potted meat in less than 5 minutes.

Introduction

Total fat extraction can be a challenge due to the potential of the fat being entrapped by the matrix. Traditional methods, such as soxhlet, have been found to be effective; however, they require lots of time, use lots of solvent, and are destructive to the sample. In the demanding food industry here is a huge need to determine fat content quickly and safely.

Beyond the food labeling needs, analyzing for food contaminants is increasingly important. When analyzing for food contaminants there is often a need to further process a sample after fatextraction. Most traditional methods destroy the sample during the fat extraction making further processing impossible. With EDGE, the fat extraction from hot dogs and potted meat is completed in under 5 min. The EDGE process is non-destructive and the extracted sample is ready for further analysis. Included in the run time is the extraction, filtration, cooling and washing process.

Extraction of Pesticides from Difficult Food Matrices

Abstract

The QuEChERS method has been shown to be practical for pesticide analysis on a number of different sample types and is increasingly being employed on more difficult matrices. Unfortunately, this process is a manual multi-step process that can be time consuming. With so many different types of food matrices and pesticide residues to be analyzed there is a need for a faster simplified extraction method. Furthermore, some matrices either by their nature or their economic value, can be difficult to analyze with just the QuEChERS method alone. In this application note we propose the EDGE™ as an alternative to the QuEChERS method for the extraction of pesticides from food matrices including known difficult matrices. With its patent pending Q-Cup Technology™ the EDGE can extract a difficult food sample, including the dispersive solid phase cleanup, in less than 5 minutes in one automated step.

Introduction

More and more consumers want to know what is in their food, particularly anything that could be harmful, such as pesticides. There is a driving need for pesticide analysis and the list of pesticides regulated throughout the world continues to increase. The QuEChERS method has become a widely accepted method to extract pesticides from food matrices. Due to the large number of pesticides to monitor and the low method detection limits, pesticide analysis can be a big challenge. Alternative methods can help aid in this challenge giving improved recoveries for difficult matrices with a faster and simplified method.

The manual multi-step process of the QuEChERS method requires multiple sample transfers and generates a lot of consumable waste. With the EDGE the sample and sorbents are together in one sample cell leading to extraction and cleanup in one step. In under 5 min the food sample is extracted using Q-Cup Technology which performs both extraction and cleanup of the sample. The collected extract is filtered, cooled and ready for analysis. Included in the run time is both the rinsing of the sample and washing of the system ensuring no carryover. EDGE offers the fastest pesticide extraction possible in one simple method.

Extraction of Phthalates from Polyethylene and Polyvinyl Chloride

Abstract

Phthalates are used as plasticizers in a wide range of common products and over recent years have garnered a lot of attention due to their potential negative health impacts. These impacts are so concerning that the use of some phthalates have been banned in children’s toys by the Consumer Product Safety Commission (CPSC). The ability to quickly and accurately extract phthalates from plastics such as polyvinyl chloride is advantageous and can help aid in ensuring the safety of the products made of these materials. With its patent pending Q-Cup Technology™ the EDGE™ can extract plastic samples in less than 10 minutes. The proposed method has been found to be faster and more effective than other methods for this application.

Introduction

Phthalates have been used since the 1950’s to soften plastics and can be found in products that most people encounter on a daily basis, such as personal care products, vinyl flooring, children’s lunch boxes, backpacks and toys. Even more alarming is that phthalates can be found in many items that young children, who are more prone to put things in their mouths, come in contact with. Phthalates have been described as dangerous chemical toxins and that can damage the liver, kidneys, lungs, and reproductive systems and have been linked to alteration of DNA integrity. Since they are not chemically bound to the plastic, phthalates are continuously being released into the environment and people are exposed through repeated contact. The extraction of phthalates from plastics needs to be a quick and simple process so that manufacturers can confidentially release products that meet the safety guidelines of the CPSC.

The extraction of phthalates from plastics is difficult for a number of reasons. First, the complexity of the samples and the low melting point of the plastic make it difficult to extract just the analyte of interest. Next, the traditional methods for extraction of phthalates are time consuming and often yield extracts that are cloudy and contain multiple co-extracts, making analysis difficult. Lastly, is the potential for unacceptable levels of carryover from sample to sample. The EDGE is capable of producing a clean, filtered, and cooled extract that is ready for analysis in less than 10 minutes. Each 10 minute extraction cycle also includes an efficient dual solvent wash which cleans the system and eliminates risk of carryover.