This accessory for WP 300 makes it possible to carry out pressure experiments. The compressive strength is determined as an important characteristic of a material. Furthermore, the compression yield point can be determined as the onset of plastic deformation of a material, at which no compressive strength can be determined.

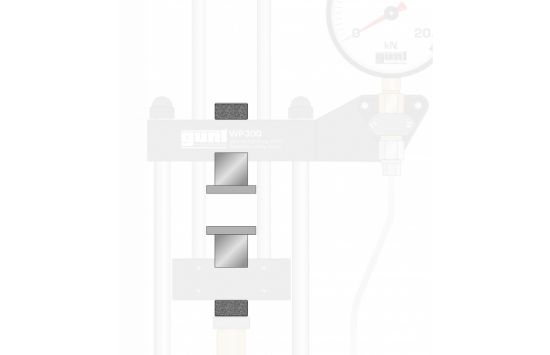

The accessory contains two pressure plates between which a specimen is positioned. The assembled compression mechanism is installed in the pressure section of the WP 300 experimental unit, between the lower crossmember and the crosshead.

In experiments, a uniaxial state of stress is produced in a geometrically defined specimen. This state of stress is produced by an external load on the specimen in the longitudinal direction via a compressive force. Then a uniform normal stress distribution prevails in the test cross-section of the specimen.

In order to determine the strength of the material, the load on the specimen is slowly and steadily increased, until the specimen ruptures.

Materials with a relatively low compressive strength or different geometry that require a larger contact surface, can be studied e.g. assembly foam, cardboard boxes, plastic bottles (lab-own compression specimens).