Rectification is an important thermal separation method in industry for separating homogeneous liquid mixtures, such as the fractionation of crude oil. Rectification represents an energy-efficient distillation process carried out in several consecutive stages.

CE 600 includes 3 interchangeable columns: a sieve tray column, a bubble cap tray column and a packed column. The separating liquid mixture can be fed to the columns at three different heights. The preheating of the

feed is possible with the help of a heat exchanger. Ethanol/water is recommended as the liquid mixture for the CE 600.

The fed liquid mixture partially evaporates on its way to the bottom of the column where it is electrically heated to boiling. The mixed vapour produced then moves upwards in the column. The mixed vapour contains a higher concentration of the component with the lower boiling point (ethanol). It leaves the top of the column and is condensed using a condenser. Part of this condensate is collected in a tank while the rest is fed back into the column as reflux. On its way downwards, it undergoes an intensive heat and material exchange with the rising mixed vapour. This exchange causes the vapour phase to become richer in ethanol and the liquid phase to become richer in water. The liquid phase moves to the bottom and can be collected in two tanks.

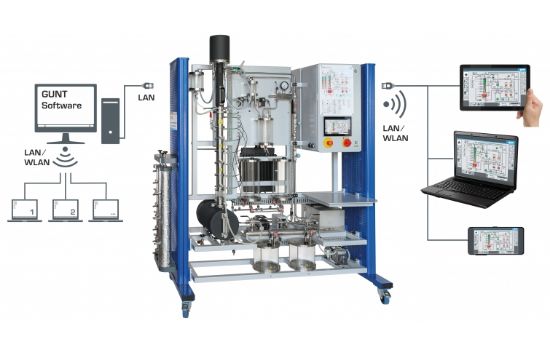

The trainer is controlled by the PLC via touch screen. By means of an integrated router, the trainer can alternatively be operated and controlled via an end device. The user interface can also be displayed on additional end devices (screen mirroring). Via the PLC, the measured values can be stored internally. Access to stored measured values is possible from end devices via WLAN with integrated router/LAN connection to the customer’s own network. Via direct LAN connection the measured values can also be transmitted to a PC where they can be analysed using the GUNT software.