Temperature

Setting temperature range

+20 to +250 °C

Setting accuracy temperature

up to 99.9 °C: 0.1 / from 100 °C: 0.5

Working temperature range

at least 10 above ambient temperature to +250°C

Temperature sensor

1 Pt100 sensor DIN class A in 4-wire-circuit

Control technology

Language setting

German, English, Spanish, French, Polish, Czech, Hungarian

ControlCOCKPIT

SingleDISPLAY. Adaptive multifunctional digital PID-microprocessor controller with high-definition TFT-colour display

Timer

Digital backwards counter with target time setting, adjustable from 1 minute to 99 days

Function SetpointWAIT

the process time does not start until the set temperature is reached

Calibration

three freely selectable temperature values

adjustable parameters

temperature (Celsius or Fahrenheit), fan speed, air flap position, programme time, time zones, summertime/wintertime

Ventilation

Fan

forced air circulation by 2 quiet air turbines, adjustable in 10 % steps

Fresh air

Admixture of pre-heated fresh air by electronically adjustable air flap

Vent

vent connection with restrictor flap

Communication

Documentation

programme stored in case of power failure

Programming

AtmoCONTROL software for reading out, managing and organising the data logger via Ethernet interface (temporary trial version can be downloaded). USB stick with AtmoCONTROL software available as accessory (on demand).

Safety

Temperature control

adjustable electronic overtemperature monitor and mechanical temperature limiter TB, protection class 1 according to DIN 12880 to switch off the heating approx. 20°C above nominal temperature

Autodiagnostic system

for fault analysis

Standard equipment

Internals

2 stainless steel grid(s), electropolished

Works calibration certificate

Calibration at +160°C

Door

fully insulated stainless steel doors with 2-point locking (compression door lock), lockable

Stainless steel interior

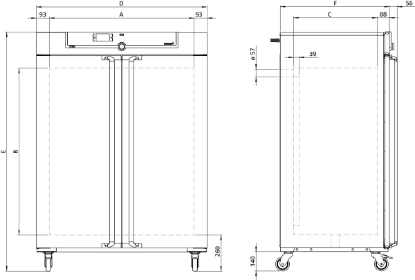

Dimensions

w(A) x h(B) x d(C): 1040 x 1200 x 600 mm (d less 39 mm for fan)

Interior

easy-to-clean interior,made of stainless steel, reinforced by deep drawn ribbing with integrated and protected large-area heating on four sides

Volume

749 l

Max. number of internals

14

Max. loading of chamber

300 kg

Max. loading per internal

30 kg

Textured stainless steel casing

Dimensions

w(D) x h(E) x d(F): 1224 x 1720 x 784 mm (d +2x56mm door handle)

Installation

on lockable castors

Housing

rear zinc-plated steel

Electrical data

Voltage Electrical load

400 V, 3 phases, 50 Hz approx. 7000 W

Temperature

Setting temperature range

+20 to +250 °C

Setting accuracy temperature

up to 99.9 °C: 0.1 / from 100 °C: 0.5

Working temperature range

at least 10 above ambient temperature to +250°C

Temperature sensor

1 Pt100 sensor DIN class A in 4-wire-circuit

Control technology

Language setting

German, English, Spanish, French, Polish, Czech, Hungarian

ControlCOCKPIT

SingleDISPLAY. Adaptive multifunctional digital PID-microprocessor controller with high-definition TFT-colour display

Timer

Digital backwards counter with target time setting, adjustable from 1 minute to 99 days

Function SetpointWAIT

the process time does not start until the set temperature is reached

Calibration

three freely selectable temperature values

adjustable parameters

temperature (Celsius or Fahrenheit), fan speed, air flap position, programme time, time zones, summertime/wintertime

Ventilation

Fan

forced air circulation by 2 quiet air turbines, adjustable in 10 % steps

Fresh air

Admixture of pre-heated fresh air by electronically adjustable air flap

Vent

vent connection with restrictor flap

Communication

Documentation

programme stored in case of power failure

Programming

AtmoCONTROL software for reading out, managing and organising the data logger via Ethernet interface (temporary trial version can be downloaded). USB stick with AtmoCONTROL software available as accessory (on demand).

Safety

Temperature control

adjustable electronic overtemperature monitor and mechanical temperature limiter TB, protection class 1 according to DIN 12880 to switch off the heating approx. 20°C above nominal temperature

Autodiagnostic system

for fault analysis

Standard equipment

Internals

2 stainless steel grid(s), electropolished

Works calibration certificate

Calibration at +160°C

Door

fully insulated stainless steel doors with 2-point locking (compression door lock), lockable

Stainless steel interior

Dimensions

w(A) x h(B) x d(C): 1040 x 1200 x 600 mm (d less 39 mm for fan)

Interior

easy-to-clean interior,made of stainless steel, reinforced by deep drawn ribbing with integrated and protected large-area heating on four sides

Volume

749 l

Max. number of internals

14

Max. loading of chamber

300 kg

Max. loading per internal

30 kg

Textured stainless steel casing

Dimensions

w(D) x h(E) x d(F): 1224 x 1720 x 784 mm (d +2x56mm door handle)

Installation

on lockable castors

Housing

rear zinc-plated steel

Electrical data

Voltage Electrical load

400 V, 3 phases, 50 Hz approx. 7000 W

Temperature

Setting temperature range

+20 to +250 °C

Setting accuracy temperature

up to 99.9 °C: 0.1 / from 100 °C: 0.5

Working temperature range

at least 10 above ambient temperature to +250°C

Temperature sensor

1 Pt100 sensor DIN class A in 4-wire-circuit

Control technology

Language setting

German, English, Spanish, French, Polish, Czech, Hungarian

ControlCOCKPIT

SingleDISPLAY. Adaptive multifunctional digital PID-microprocessor controller with high-definition TFT-colour display

Timer

Digital backwards counter with target time setting, adjustable from 1 minute to 99 days

Function SetpointWAIT

the process time does not start until the set temperature is reached

Calibration

three freely selectable temperature values

adjustable parameters

temperature (Celsius or Fahrenheit), fan speed, air flap position, programme time, time zones, summertime/wintertime

Ventilation

Fan

forced air circulation by 2 quiet air turbines, adjustable in 10 % steps

Fresh air

Admixture of pre-heated fresh air by electronically adjustable air flap

Vent

vent connection with restrictor flap

Communication

Documentation

programme stored in case of power failure

Programming

AtmoCONTROL software for reading out, managing and organising the data logger via Ethernet interface (temporary trial version can be downloaded). USB stick with AtmoCONTROL software available as accessory (on demand).

Safety

Temperature control

adjustable electronic overtemperature monitor and mechanical temperature limiter TB, protection class 1 according to DIN 12880 to switch off the heating approx. 20°C above nominal temperature

Autodiagnostic system

for fault analysis

Standard equipment

Internals

2 stainless steel grid(s), electropolished

Works calibration certificate

Calibration at +160°C

Door

fully insulated stainless steel doors with 2-point locking (compression door lock), lockable

Stainless steel interior

Dimensions

w(A) x h(B) x d(C): 1040 x 1200 x 600 mm (d less 39 mm for fan)

Interior

easy-to-clean interior,made of stainless steel, reinforced by deep drawn ribbing with integrated and protected large-area heating on four sides

Volume

749 l

Max. number of internals

14

Max. loading of chamber

300 kg

Max. loading per internal

30 kg

Textured stainless steel casing

Dimensions

w(D) x h(E) x d(F): 1224 x 1720 x 784 mm (d +2x56mm door handle)

Installation

on lockable castors

Housing

rear zinc-plated steel

Electrical data

Voltage Electrical load

400 V, 3 phases, 50 Hz approx. 7000 W